파워스타트 시스템의 홈페이지에 방문하신 것을 환영합니다.

Breaker Trip Units

Breaker trip units (‘protection units’) safeguard your circuit breakers from the damage that can be caused by power fluctuations.

|

| AMP-SAFE PRO trip units directly replace the Schneider Electric trip unit in Masterpact-M circuit breakers |

3rd party trip units represent an economical way to extend the life of existing equipment without having to go to the expense of new circuit breakers.

The lifecycle of a circuit breaker and trip unit

Circuit breakers are designed to deliver years of reliable, untroubled service. But they don’t last forever.

|

| AMP-SAFE PRO trip units economically extend the life of circuit breakers and reduce maintenance downtime |

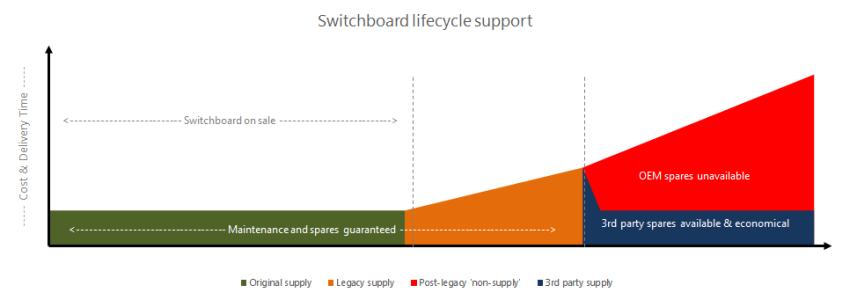

During the time when a circuit breaker is actively marketed and promoted the manufacturer will offer full service, support and parts either direct to end-users or through a network of worldwide distributors. The green area on the chart represents this period. During this time support is easy to access and economical. The manufacturers and their distributors actively support and develop what is, at that time, their current product range. Their expertise and support is focused on these products.

Once a circuit breaker is superseded by a newer model support continues but it’s nature changes (this is represented by the orange area on the chart). The end-user is affected by this change:

- Spare parts are downgraded from prime stock so stock levels fall and delivery times increase.

- High volume production of spare parts falls so the unit price rises, increasing the cost of maintaining older systems.

- Expertise starts to decline as technical staff switch focus onto newer products and experienced staff leave the industry.

This type of lifecycle is common for most technical products. However, the circuit breaker and trip unit market is fundamentally different to others. Whereas the next generation of television or computer offers fundamental improvements over its predecessor, newer circuit breakers are evolutionary at best. The differences are nominal. Electricity supply has stayed the same so there’s rarely a compelling technical reason to upgrade from one model to another. In some countries regulatory changes may force a software upgrade but it’s unusual for legislation to make a whole category of equipment redundant.

It is difficult to avoid the conclusion that a supplier’s commercial desire to see circuit breaker upgrades is greater than the end-user’s technical need for them.

Most manufacturers offer at least ten years support for circuit breakers after their production run finishes. At this point, end-users enter the red area of the chart. Original trip units and other spare parts are no longer available from the manufacturer. They are only available in limited quantities from specialist distributors. The impact can be dramatic and uncomfortable for end-users:

- No official support is available.

- Supplies of trip units and other spare parts decline and are not replenished.

- Spare part prices rise in a classic seller’s market.

In normal circumstances this is the point at which an upgrade is logical. But it’s hard to justify an upgrade for for circuit breakers:

- It can be difficult to identify a technical reason why the end-user needs a new circuit breaker. Electricity’s still the same. The regulations are still the same. The infrastructure’s still the same.

- The majority of a circuit breaker can be perfectly serviceable but the unit won’t work because one specific – and often small – part has failed. The culprit is often the trip unit, the one part that’s specifically designed as a failsafe.

This is the point at which the 3rd party after-market can play a part. This is represented by the blue area of the chart.

This is a golden opportunity for end-users to continue using old equipment to its full potential at a fraction of the cost of a full replacement or upgrade.

The implications of replacing circuit breakers instead of trip units

Circuit breaker installations are not simple. They require planning, designing, approvals and certification. This comes at a price.

|

| Using a 3rd party trip unit is far more economical than replacing an entire circuit breaker |

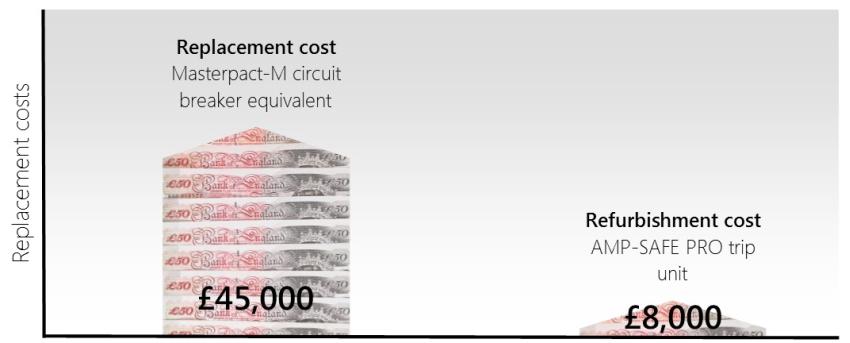

Cost. The simple cost of a circuit breaker replacement is the main reason not to do it. The cost of replacement will vary from breaker to breaker but it is reasonable to expect a total bill of about £45,000 for a full replacement. The cost of replacing trip units and other components can be a small fraction of that.

Disruption to customers. If the circuit breaker serves customer-facing resources such as web servers, phone switchboards and IT systems it is inevitable that customers will be affected by a major upgrade. Advance notice helps customers plan ahead but the notice itself imposes extra workload on other departments in your business. Even with notice, customers will not welcome a disruption.

Extra workload. Your support departments already have a substantial project list. Adding circuit breaker replacements to it does nothing to help project completion. Changing trip units is a minor upgrade by comparison.

Training. Your staff have to be trained so they can properly support the new circuit breaker; they don’t have to be trained to support the circuit breaker they’ve been using for the past decade.

The advantages of using trip units to extend circuit breaker life

In one sense, the advantages of extending circuit breaker life is merely an exercise in avoiding the negative implications of an upgrade as detailed above.

But there is also a more fundamental reason why circuit breakers should be retained as long as possible: avoiding needless waste. Many circuit breakers are replaced when one critical – and perhaps inexpensive – component is unavailable. Trip units (circuit breaker protection units) are often the culprits because they’re designed to fail to protect the main circuit breaker. They make sure the circuit breaker stays perfectly serviceable.

It’s easy to draw comparisons to other situations in which we don’t replace the ‘main unit’ when a component fails. We don’t replace a car when its windscreen breaks or its tyres wear out. We don’t change a light when its bulb blows. We don’t replace heating boilers when a valve leaks.

The advantages of extending the life of a circuit breaker by using 3rd party components like AMP-SAFE PRO trip units can be summarised as:

- Enhances system reliability by replacing trip units and other likely points of failure

- Reduces maintenance costs by increasing reliability and limiting the scope of the upgrade. Replacing trip units can cost as little as £8,000. Replacing the whole circuit breaker can approach £45,000.

- Reduce the ancillary costs that are easily omitted from project budgets: design time, marketing time (e.g. announcing disruptions), administration time (e.g. for working around disruptions), etc.

- Reduces maintenance time increasing reliability and limiting the scope of the upgrade

- Reduces disruption to internal and external customers by completing an upgrade in minutes instead of hours

- Maintains compliance by ensuring equipment passes regulatory testing

- Ensures safety by replacing unreliable components that could trigger a critical system failure

- Reduce WEEE and recycling obligations by replacing one or two small components instead of a complete circuit breaker

- Limits equipment overheads by deferring or cancelling an expensive circuit breaker replacement

New opportunities

Most 3rd-party manufacturers of after-market components promote their products as being ‘as good as the original’. This is not always true. They are often much better than the original. A component designed and built years after the original part was designed has numerous advantages:

- They can use materials or components that are technically or materially superior to those that were available when the original equipment was designed. For example, plastic is a lighter and perfectly adequate replacement for metal in many situations.

- They can use materials or components that are much less expensive than those that were available when the original equipment was designed. Almost all electronic components are cheaper now than they were ten years ago.

- They can be designed to overcome shortcomings that have been identified during the life of the original equipment

The only note of caution to be observed when extending the life of a circuit breaker is that it can only be a temporary reprieve – all circuit breakers will have to be replaced eventually. Extending their life postpones the expense until the time when it is suits the end-user, not the manufacturer.

Masterpact M trip unit: AMP-SAFE PRO

The Masterpact M circuit breaker has an installed base running into tens of thousands. And yet, since factory support was discontinued in 2014, thousands of users have been left without a source for replacement trip units. The AMP-SAFE PRO solves that problem. The AMP-SAFE PRO is the only UL and CE-listed replacement for STR…

Find out more