파워스타트 시스템의 홈페이지에 방문하신 것을 환영합니다.

IPU Fuel Conditioning Programmes

|

| IPU is the only business partner you need for a full Fuel Conditioning Programme |

IPU’s four step fuel conditioning process

IPU’s four-part Fuel Conditioning Programme presents the simplest and most economical route to clean, dry, reliable fuel. It includes:

- 1. DieselCheck Fuel Testing

- 2. ClearTank Fuel Cleaning

- 3. Diesel Defence Fuel Polishing

- 4. ADV Fuel Stabilisation

The beauty of a Fuel Conditioning Programme is its Amazon-inspired simplicity. One company handles everything to do with maintaining your fuel quality. It’s is the ‘sort it and bill me’ solution that fits the threat.

DieselCheck Fuel Testing

|

| Testing alerts you to problems introduced by contaminated deliveries or tank breaches. |

Regular testing alerts you to problems introduced by contaminated deliveries or tank breaches. Like most issues early detection is key to treating the problem before it becomes serious. IPU offers regular testing as a part of a Fuel Conditioning Programme. We can also offer a single DieselCheck Fuel Test by an IPU expert and training for your staff to conduct self-tests.

ClearTank Fuel Cleaning

|

| IPU’s ClearTank cleaning service is a one-time process that prepares your fuel for long-term conditioning. |

Cleaning is an essential part any fuel conditioning programme. Just as you wouldn’t wax a dirty car, we don’t polish dirty fuel. IPU’s ClearTank service cleans your stored fuel without requiring a diesel uplift, without requiring man-entry into your tanks and without losing half your stored fuel in the process. It removes water, solid particulate and microbial contamination. It’s discrete, economical and effective.

Diesel Defence Fuel Polishing

|

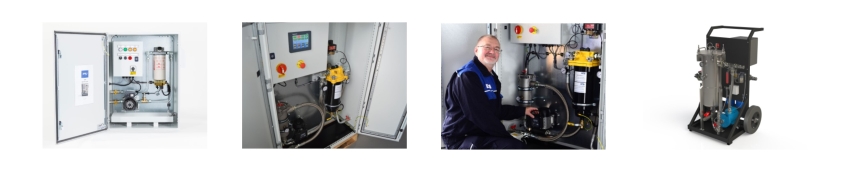

| IPU’s Diesel Defence on-tank and mobile polishing units keep fuel clean, dry and ready to power your critical applications. |

The adoption of biodiesel is 2011 means clean fuel does not stay clean. Biodiesel attracts water and water encourages microbial growth (aka the diesel bug). IPU’s Diesel Defence on-tank and mobile polishing units keep fuel clean, dry and ready to power your critical applications.

ADV Fuel Stabilising

|

| IPU’s ADV Regulator neutralises the tiny molecules of water and contaminants that are too small for polishing units. |

IPU’s cleaning and polishing systems ensure that your fuel exceeds the standards set by EN 590 (for water contamination) and ISO 4406 (for particulate contamination). But they don’t remove all water; that’s impossible. Water is one of the component parts of biodiesel. IPU’s ADV Regulator neutralises the tiny molecules of water and contaminants that are too small for polishing units.

Since when has fuel needed conditioning?

We like to think that fuel we use in December will be as good as when we stored it in July. In an ideal world, it would be. In reality, the fuel we buy is a blend of petrochemical diesel and FAME, a biological element that reduces the damage caused by burning the fuel. Diesel has contained 7% FAME since 2011; that proportion will steadily rise. Whilst biodiesel is a great idea for the environment but it’s a problem for anyone who stores fuel.

Under normal conditions it is now widely accepted that modern diesel blends will only remain in a useable condition for 6 to 12 months. After this, fuel begins to degrade and, depending on the type and severity of the contamination, could cause a engine failure.